In the middle of 2022, Disney (Disney) and its 3 people came to our factory for surprise inspection and social responsibility inspection. After a comprehensive on-site review, Disney finally determined that our factory met the standard requirements and the inspection passed successfully. As early as 2016, in order to meet the production requirements of Disney orders, our company applied for and passed the Disney audit and certification, which gained international recognition and laid a firm foundation for long-term development.

The main concern of this Disney surprise inspection was the social responsibility performance of the factory. In terms of employment, whether wages and salaries and benefits meet local laws and regulations, whether employees’ human rights are respected, and whether the working environment is in line with occupational health and safety, Disney has set its own factory inspection standards: the Global Labor Standards (ILS program). Under the program, factories must meet and consistently comply with the MCS standards (Minimum Compliance Standards) in order to pass inspection and continue to retain Disney qualification certification.

The Disney Factory Inspection Program has been underway for a long time, but the compliance rate so far is only 10%. This one-time passing of our factory means that we have been implementing a production management system that meets international requirements and has reached the standard in respecting human rights and strict requirements of health and safety and hygiene, ahead of our peers and even most domestic companies.

01 Own factory

Intelligent upgrade of core equipment

We established our own factory in 2012, with an area of 8000m² and more than 300 employees. Our business covers 3C consumer electronics, fast fashion and other industries, from concept to design, production, packaging and logistics, we are committed to providing customers with comprehensive and systematic product solutions.

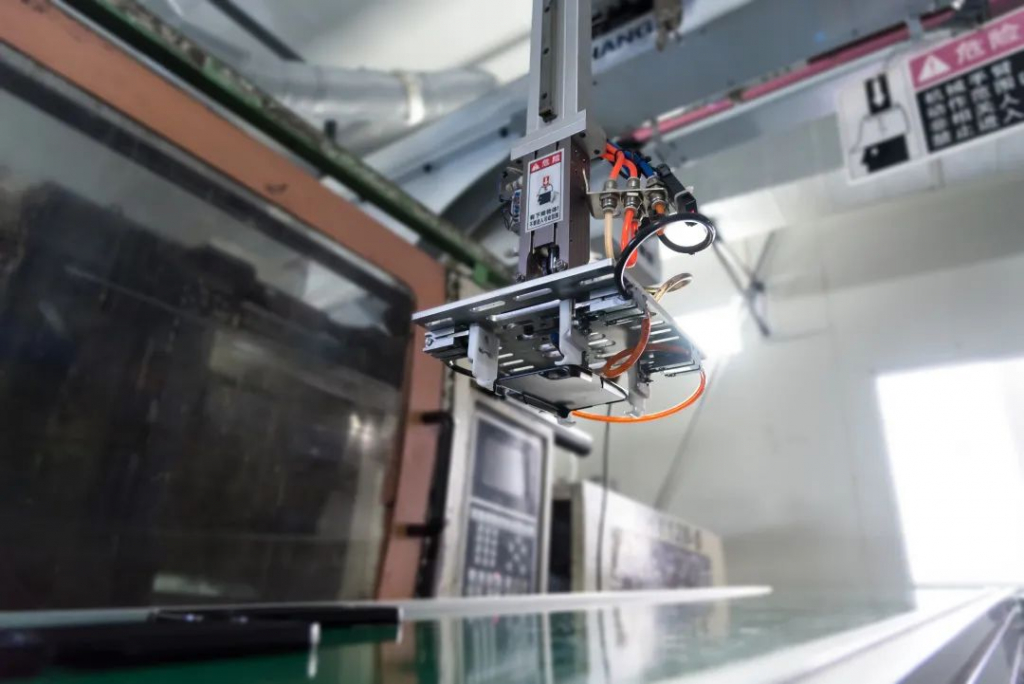

With years of experience in R&D and production, and combined with the latest application technology, the core equipment of the factory is also continuously upgraded. Injection molding machines, robots and a variety of quality inspection equipment in the laboratory have been upgraded to be more intelligent and automated, greatly improving production efficiency while reducing labor costs. The equipment upgrade is to create a safe, stable and efficient workplace for employees on the one hand, and to accelerate the leap and transformation of the factory from traditional manufacturing to modern intelligent manufacturing on the other.

02 Qualification

Adhere to the road of high quality development

Our factory passed the certification of “Environmental Impact Assessment for Construction Projects” in 2017 and became a benchmark factory in the park, and has passed more than ten certifications in the following six years, such as BSCI, sedex4p, W-CA social responsibility certification, Disney audit certification and GRS certification.

Each certification is an intangible asset, marking that our company has obtained the internationally recognized “market pass”, which means that our production management system, quality management system and technical level system have taken a forward-looking step towards standardization, standardization and specialization, and it also confirms our determination to pursue quality and lead the development of the industry. The company’s production management system, quality management system and technical level system have taken a forward-looking step towards standardization and specialization.

03 Innovation R&D

Establishment of Product Innovation Center

In order to provide customers with more timely and professional product solutions, our company set up a product innovation center with international advanced level in 2022. The department, headed by the CEO, has introduced talents in process, material and production to increase the development of new materials and new processes for products and invest in market research and analysis. New products, new materials, new processes, and unique market data analysis will be continuously pushed out every month in the future.

In 2022, we have upgraded our corporate strategy and will focus on ODM services for five categories of cell phone cases, headphone cases, computer bags, tablet covers and watch straps in the next five years, and will continue to push the boundaries in terms of product appearance, engineering design and functionality to flexibly meet the customization needs of different brands around the world. The value proposition of “full chain ecosystem, full system certification, comprehensive testing professional laboratory, and consultant type flexible customization” is delivered to customers.

The passing of the Disney factory inspection certification is a high recognition of our efforts. In the 3C electronic parts industry for more than ten years, we continue to advance in the direction of bringing excellent “Made in China” to the global market.

In the future, our company will keep improving and insist on international or even higher than international standards to achieve the common development of enterprise and staff and provide more quality products for global customers.

Product images are taken from the network, please contact to remove the infringement