Introduction: How Best Phone Case Manufacturers Evaluate Materials in 2026

Choosing the right phone case material is no longer a simple design decision. For global brands, distributors, and wholesalers, material selection directly affects production efficiency, cost control, and long-term product performance. As a result, best phone case manufacturers must evaluate materials from both a user and factory perspective.

Among all available options, silicone phone cases and TPU phone cases remain the most frequently requested materials. From the viewpoint of best phone case manufacturers, these two materials represent very different production logics, tooling requirements, and market positioning. Understanding these differences helps buyers make smarter sourcing decisions in 2026.

As a manufacturing-focused factory, C&T works closely with international clients to analyze material suitability before mass production. This approach helps buyers reduce sourcing risks and secure stable bulk supply from an experienced production partner.

Understanding the Main Phone Case Materials Used by Best Phone Case Manufacturers

What Is TPU (Thermoplastic Polyurethane)?

TPU is a flexible thermoplastic elastomer widely adopted in industrial phone case manufacturing. It combines elasticity, abrasion resistance, and structural stability, making it ideal for injection molding.

From the perspective of best mobile phone case manufacturers, TPU offers predictable processing behavior and high output efficiency. Its material properties are well documented across the plastics industry, including in technical references such as https://en.wikipedia.org/wiki/Thermoplastic_elastomer, which explains why TPU remains a preferred choice for protective accessories.

For buyers seeking OEMODM Phone cases, TPU enables faster tooling validation and smoother transitions from sample development to mass production, especially for global wholesale programs.

What Is Silicone?

Silicone is a rubber-like polymer known for its soft-touch feel and excellent heat resistance. It is commonly processed through compression molding or liquid silicone rubber systems.

While silicone delivers a premium tactile experience, best phone case manufacturers often consider its longer curing time and higher tooling cost. According to polymer material insights published by the European plastics industry,https://plasticseurope.org/knowledge-hub/plastics-explained/, silicone processing typically requires more controlled production environments.

Because of these factors, silicone is usually recommended for limited-edition designs or brand-focused projects rather than large-scale wholesale production.

Performance Comparison: Why Best Phone Case Manufacturers Compare TPU vs Silicone Carefully

Durability and Protection Performance

TPU phone cases excel at shock absorption and structural recovery. After repeated impacts, TPU maintains its shape and protective capability. Silicone, however, may stretch or deform permanently after long-term use.

Since durability directly affects product returns and customer satisfaction, best phone case manufacturers often recommend TPU for protective designs aimed at international distribution and long-term sales cycles.

Flexibility, Grip, and User Handling

Silicone provides a softer, more skin-friendly grip that appeals to lifestyle-oriented brands. TPU feels firmer but remains flexible enough for easy installation and removal.

From a factory testing perspective, TPU demonstrates better edge retention and dimensional stability. For clients working with a reliable phone case supplier, this stability results in fewer post-production issues and more consistent quality control.

Design, Finish, and Visual Options

TPU supports transparent, frosted, and matte finishes without additional surface treatment. Silicone usually requires coating or oil spraying to achieve uniform color and surface texture.

As a result, best selling phone case manufacturers frequently select TPU when visual clarity, color accuracy, and repeatability are critical for brand consistency.

Manufacturing Considerations from Best Phone Case Manufacturers

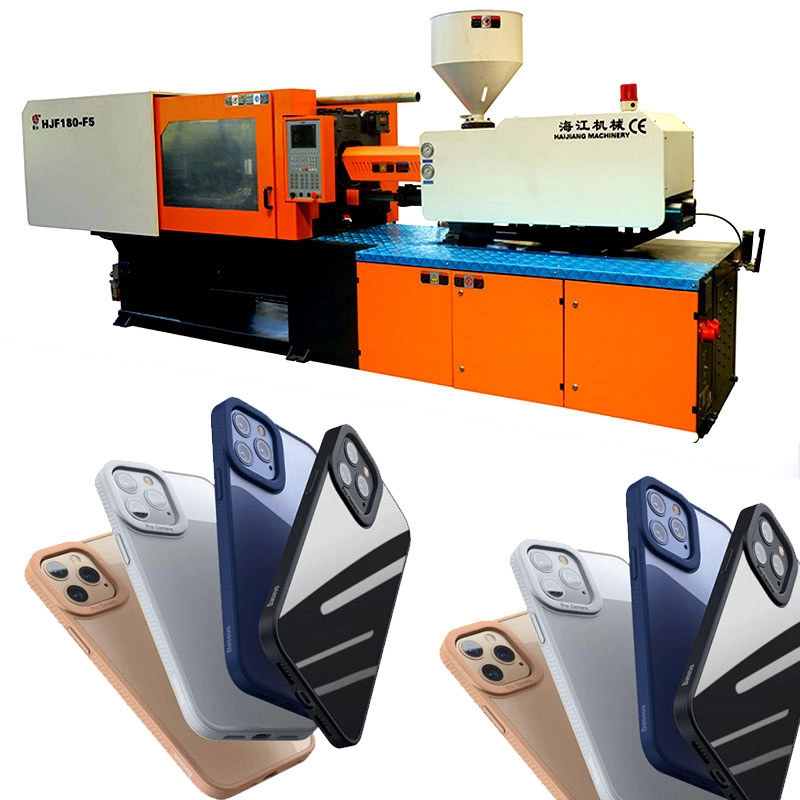

Tooling Efficiency and Production Scalability

Injection molds used for TPU generally offer longer service life and faster production cycles. Silicone molds experience higher wear due to material viscosity and curing requirements.

For large-scale phone case wholesale programs, TPU provides stronger scalability and cost predictability. This advantage is especially important for upcoming flagship launches, including iphone 17 phone case wholesale projects that require tight timelines and stable output.

Quality Control and Yield Rate

TPU defects are typically identified during the molding stage, allowing immediate adjustments. Silicone defects often appear after curing, increasing inspection time and rework costs.

Factories like C&T focus on optimizing yield rates through standardized processes, which is why many international buyers prefer experienced phone case makers with in-house production rather than intermediaries.

Advantages and Limitations: A Factory Perspective from Best Phone Case Manufacturers

TPU Advantages

Strong impact resistance

High production consistency

Flexible design applications

Silicone Advantages

Soft-touch premium feel

Excellent heat resistance

Comfortable grip for end users

While both materials have clear benefits, best phone case manufacturers generally prioritize TPU for mainstream production due to its efficiency, reliability, and scalability.

Matching Material Choice to Market Demand in 2026

Everyday Usage and Global Distribution

For everyday devices and international markets, TPU remains the dominant choice. Buyers working with a long-term phone case supplier benefit from consistent delivery schedules and stable pricing when TPU is used as the primary material.

Customization and Branding Strategy

Silicone is better suited for short-run, design-led collections. However, buyers sourcing from experienced phone cover companies often choose TPU for repeat orders and long-term growth strategies.

C&T supports both materials and helps clients evaluate which option best matches their target market, budget, and production volume.

Why Global Buyers Choose C&T as Their Manufacturing Partner

C&T is a factory specializing in custom and wholesale phone case manufacturing rather than retail sales. Its production capabilities cover tooling development, material optimization, and stable mass production for international clients.

As an experienced custom phone case manufacturer, C&T supports ODM and OEM projects with strict quality control, competitive factory pricing, and responsive engineering support. Brands and wholesalers looking to source phone cases in bulk are encouraged to work directly with C&T to reduce costs, improve efficiency, and ensure reliable long-term supply.

Conclusion: What Best Phone Case Manufacturers Recommend for 2026

After evaluating durability, scalability, design flexibility, and cost efficiency, best phone case manufacturers generally recommend TPU phone cases as the primary material for 2026. Silicone continues to play an important role in specific branding scenarios, but TPU remains the most practical choice for large-scale manufacturing.

For buyers planning future sourcing strategies, partnering directly with a proven factory like C&T ensures material decisions align with real production capabilities. If you are planning to purchase phone cases in bulk or develop custom designs for global markets, sourcing directly from C&T provides a competitive advantage in quality, pricing, and delivery reliability.