About Injection Phone Case Manufacturing

Discover how injection phone case manufacturing with proprietary mold designs empower B2B businesses to elevate branding, ensure product durability, and meet bulk order demands.

Learn about material options, cost-saving strategies, and seamless production workflows tailored for global markets.

As B2B buyers increasingly prioritize durability and cost-efficiency, our proprietary injection mold technologies set new standards for OEM/ODM partners.

Fast, Durable, Customizable.

Injection molding is the core technology for producing cost-effective phone cases, especially suitable for the stringent requirements of durable phone case suppliers.

The whole process is as intuitive as “customizing a cake”:

First, design a unique mold according to your phone model (such as the latest iPhone or Samsung model) – this is the advantage of private mold manufacturing, ensuring that every detail fits perfectly;

Then, heat the anti-drop TPU or lightweight PC materials into liquid, inject them into the mold for rapid molding;

Finally, after cooling and demolding, you can get a highly consistent finished product.

Why Choose Injection Phone Cases for Bulk Customization?

Injection molding delivers unrivaled precision and consistency for large quantity orders.

By using proprietary molds, businesses can create cases with intricate designs, logos, or textured finishes that align perfectly with brand identity.

This method ensures durability, scratch resistance, and compatibility with wireless charging—critical features for premium B2B clients.

Benefits of Using Own Mold Design

Brand Exclusivity

Protect your unique design IP while offering customers a product unavailable elsewhere.

Cost Efficiency

Eliminate per-unit licensing fees; molds last for 800,000+ cycles, reducing long-term expenses.

Faster Turnarounds

Pre-approved molds streamline production, enabling 8-15 day lead times for repeat orders.

Material Innovations for Global Markets

From shock-absorbent TPU to eco-friendly biodegradable polymers, injection molding supports diverse material choices:

TPU/PC Hybrids: Ideal for rugged cases.

Recycled Plastics: Meet EU sustainability mandates.

Anti-Yellowing Coatings: Ensure aesthetic longevity.

How to Start Your Custom Phone Case Project

- Step 1: Understand Your Target Customer

- Step 2: Choose Your Niche

- Step 3: Design and Branding

- Step 4: Source Quality Materials and Manufacturers

- Step 5: Establish Sales Channels

- Step 6: Marketing and Growth

Find more details here – Step-by-Step Guide: How to Start Your Own Phone Case Brand

Ready to Dominate the Market?

Contact us today for a mold design quote and free sample—transform your brand vision into a high-demand product!

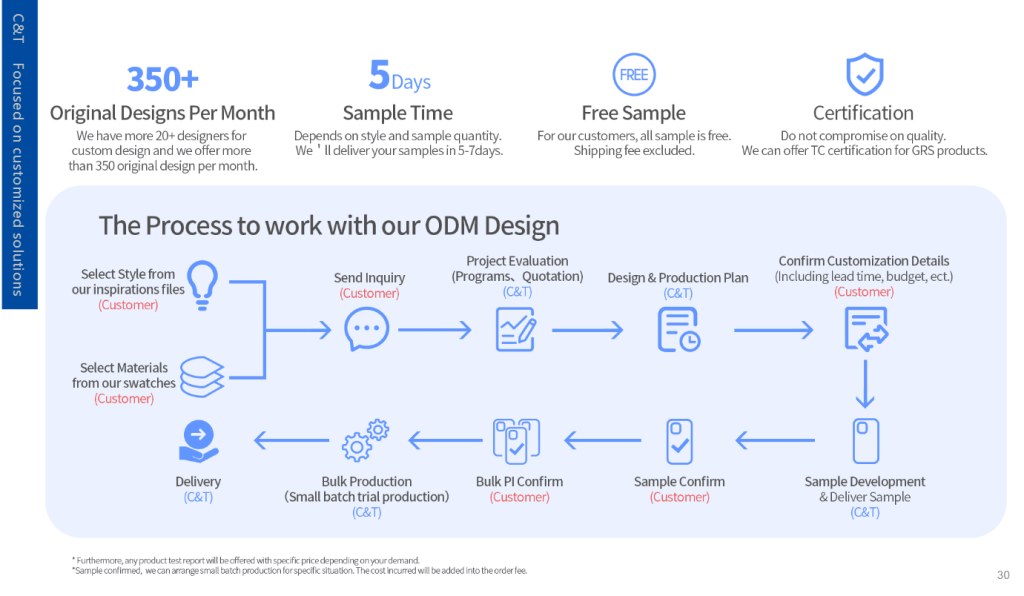

The Process to work with our ODM Design – Contact us