About Our Phone Case Workshops

C&T has 8000 square meters of its own automated factory, with injection molding, sewing and packaging three major phone case workshops, forming a complete production chain.

The three pillars of the phone case manufacturing process: precision injection moulding, hand-stitched leather and sustainable packaging –

Showing how our workshop combines advanced technology, craftsmanship and environmentally friendly practices to meet the needs of our customers.

What Does Our Phone Case Workshops Do?

Injection Workshop: Precision Engineering for Durable Designs

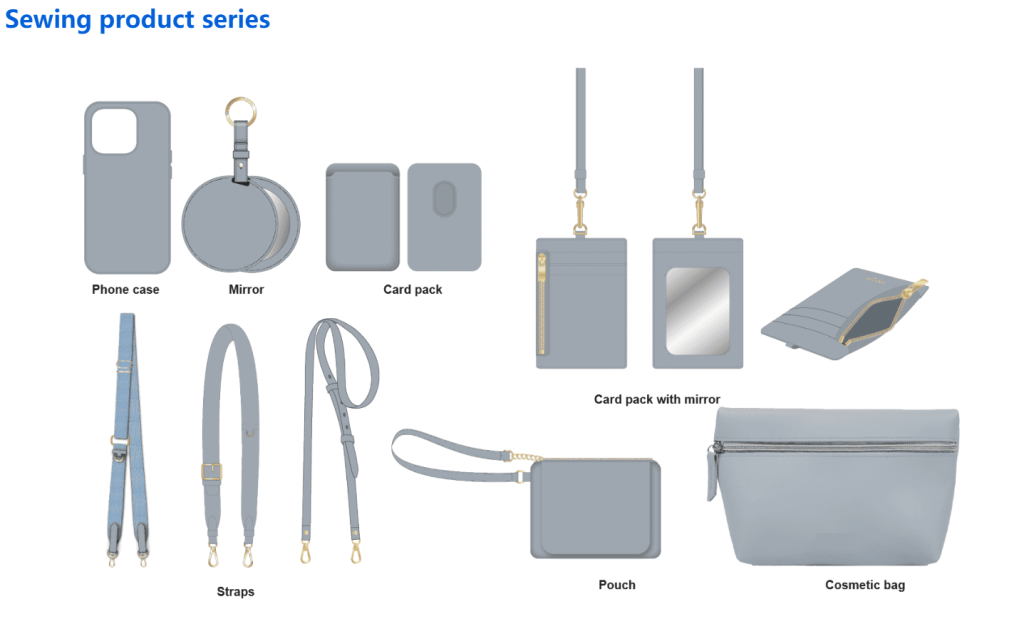

The injection molding workshop focuses on the production of a series of high-quality mobile digital accessories such as:

Mobile phone cases, AirPod cases, Watch bands, Tablet covers, Computer covers and brackets.

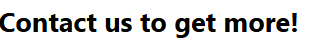

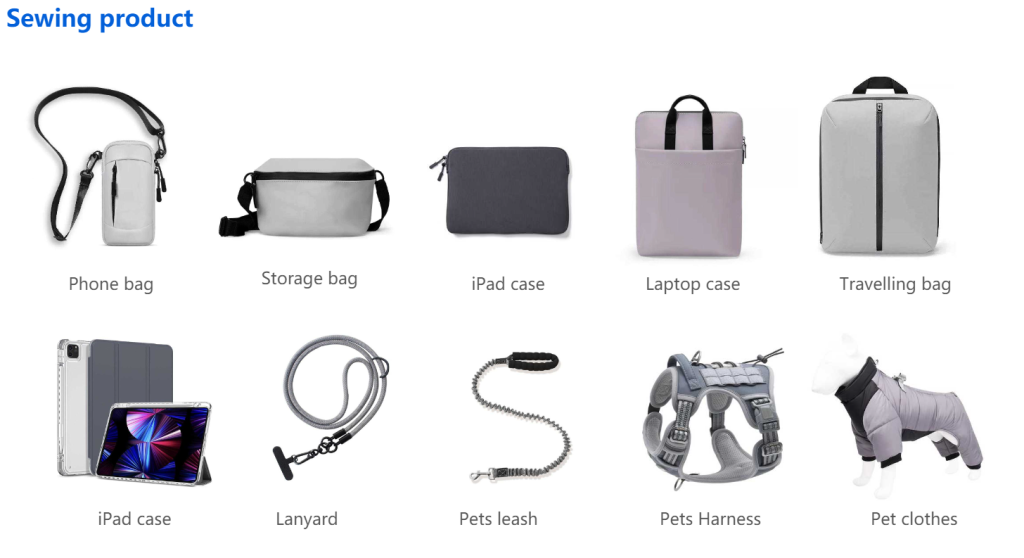

Sewing Workshop: Artisan Craftsmanship Meets Modern Technology

Sewing workshop is focused on the manufacture of multi-functional handbag series, including mobile phone bags, computer bags, storage bags, straps, leash and other pet products.

- Monthly output: 36+ million/month

- Production equipment: 40+ sets

- X-ray needle inspection machine

Packing Workshop: Secure, Sustainable, and Brand-Ready Presentation

Our packing workshop ensures every phone case arrives flawlessly while aligning with Europe’s sustainability goals. From biodegradable wraps to retail boxes, we offer tailored solutions that enhance brand value.

- Packaging workshop – Automation equipment

- Automatic Barcode Scanner – Efficient and Accuracy-Enhancing

- Packaging Automation – Cost Reduction and Efficiency Improvement

By integrating advanced injection molding technology, fine leather craftsmanship and environmentally friendly packaging, our production workshop aims to empower partners, prioritize scalability, compliance and brand consistency, and is committed to making mobile phone cases stand out in quality, beauty and sustainability.