Why Phone Case Tests are Important?

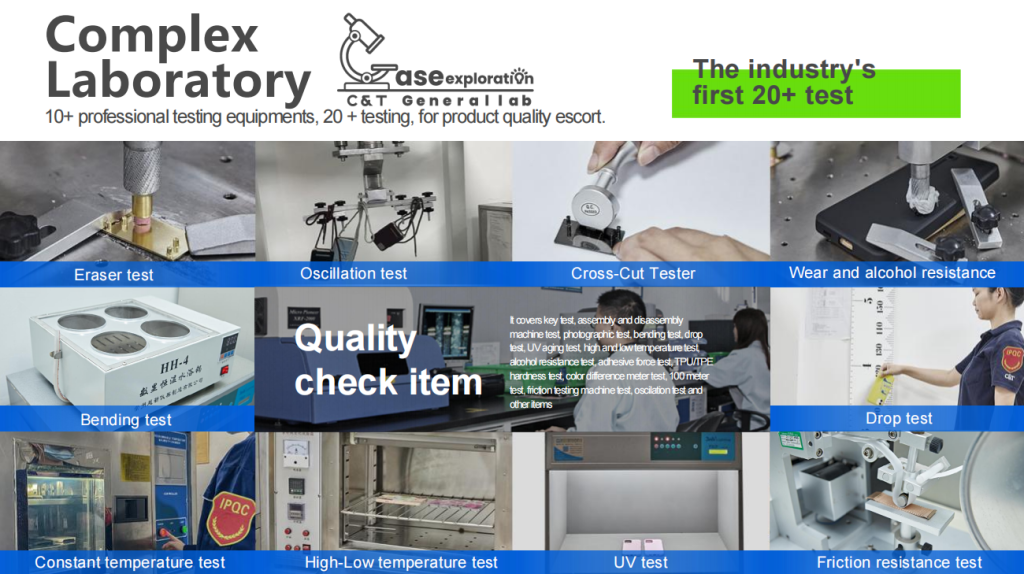

We know clearly that the quality of each product is an important factor in building brand vitality. Learn how phone case tests ensure product durability, compliance with EU standards, and customer satisfaction while boosting your brand’s credibility in competitive markets.

Types of phone case tests:

All materials(leather, PU, TPU, etc.), safety test, screen test, glue test, hardware test.

Magnetic Test: Ensuring Secure Attachment

Validate the strength and consistency of magnetic components in MagSafe compatible phone cases.

Tests simulate repeated attachment/detachment cycles to ensure magnets retain grip without weakening over time.

This is vital for cases designed for car mounts, wallets, or accessories, aligning with EU safety standards for electromagnetic compatibility.

High and Low Temperature Test: Defying Extreme Conditions

Expose phone cases to mimic harsh environments (e.g., winter cold or summer heat).

Assess material expansion/contraction, adhesive integrity, and touchscreen responsiveness.

This ensures products withstand daily use.

Drop Test: Validating Impact Resistance

Conduct controlled drops onto concrete or hard surfaces at multiple angles.

Measure shock absorption, corner reinforcement, and screen/camera lens protection.

Yellowing Resistance Test: Preserving Aesthetic Appeal

UV exposure tests simulate long-term sunlight exposure to evaluate yellowing or discoloration in clear or light-colored cases.

This test is key for maintaining visual appeal, especially for eco-friendly materials prone to oxidation.