Introduction: Material is the Game Changer in phone case Success

Important: In the mobile accessory industry, the choice of material for a phone case is often the determining factor between success and missed opportunities.

Drawing on extensive experience as a manufacturing operator, we understand that every material sample holds the potential to either boost or hinder market conversion.

For wholesalers, selecting the right material not only addresses market demands but also reduces after-sales issues. In this guide, we examine five mainstream materials from a production standpoint, offering tailored procurement strategies.

1.Silicone: The Economical Champion

Key Advantages of Silicone

Robust Impact Protection: With drop tests from heights of 3 meters showing a success rate exceeding 95%, silicone is a reliable defender against daily mishaps.

Customization Ready: Its compatibility with 3D embossing and luminous printing makes it ideal for innovative design trends.

Long Shelf Life: Resistant to weather variations, silicone maintains quality for up to two years in storage.

Applicable Scenarios:Silicone-based phone case models are perfect for corporate promotional gifts and exhibition giveaways, where low unit costs are crucial.

It is also favored in children’s protective designs due to its pliable nature.

Additionally, markets in Europe and North America have shown a strong preference for silicone in drop-protection categories.

Caution:

Note that Liquid Silicone Rubber (LSR) can cost up to 40% more than standard silicone.

For applications requiring baby-grade safety certifications or extreme winter resilience (below –20 °C), careful material selection is essential.

2.TPU: The Art of Balancing Clarity and Durability

Why Choose TPU?

Bare-Metal Aesthetics: Ultra-thin TPU designs, as slim as 0.8mm, can achieve a near-original look of the device.

Eco-Friendly Compliance: Recyclable and compliant with EU REACH standards, TPU offers a responsible choice without compromising performance.

Advanced Manufacturing: Innovative IML (in-mold labeling) technology enables full-color gradient patterns that elevate visual appeal.

Purchasing Insights:Transparent frosted phone case designs are particularly popular—Amazon’s best sellers show a 38% preference for this style.

.jpg)

When considering TPU, ensure you distinguish between conventional TPU and enhanced bulletproof TPU, which increases puncture resistance by up to 300%.

A starting order of around 3,000 units is usually ideal to balance mold costs and production efficiency.

3.PC: Visual Excellence for Market Impact

.jpg)

Standout Features of PC Material

Precision Printing: PC allows for fine line printing as thin as 0.05mm, making it perfect for luxury, co-branded models.

Upgraded Textures: Options like electroplated or matte finishes can add a premium feel, boosting perceived value by 30%–50%.

Lightweight Advantage: Weighing 40% less than silicone counterparts, PC aligns with modern minimalist consumer trends.

Risk Management:While offering impressive aesthetics, PC’s drop resistance is lower compared to other materials.

Combining it with an airbag structure might incur a 15% additional cost.

In colder climates, PC may become brittle, so integrating a 10% ABS modification is recommended.

Mixed Materials: The High-End Market’s Secret Weapon

Innovative Material Combinations

Enhanced Durability: Combining a PC back panel with a TPU frame can boost bending resistance by 200%.

Luxury Appeal: Merging carbon fiber textures with Kevlar creates a sophisticated look, often leading to an 80% increase in unit price.

Eco-Friendly Options: Blending wooden accents with silicone wrapping caters to environmentally conscious consumers, raising Instagram engagement by 45%.

Customization Tips:

Consider a material ratio, such as 70% TPU combined with 30% PC, to achieve a balanced performance profile.

For exclusive textures, dedicated mold designs with an MOQ of around 5,000 pieces may be required.

Specialty Materials: The Differentiated Choice for Niche Markets

Unique Options with High Profit Potential

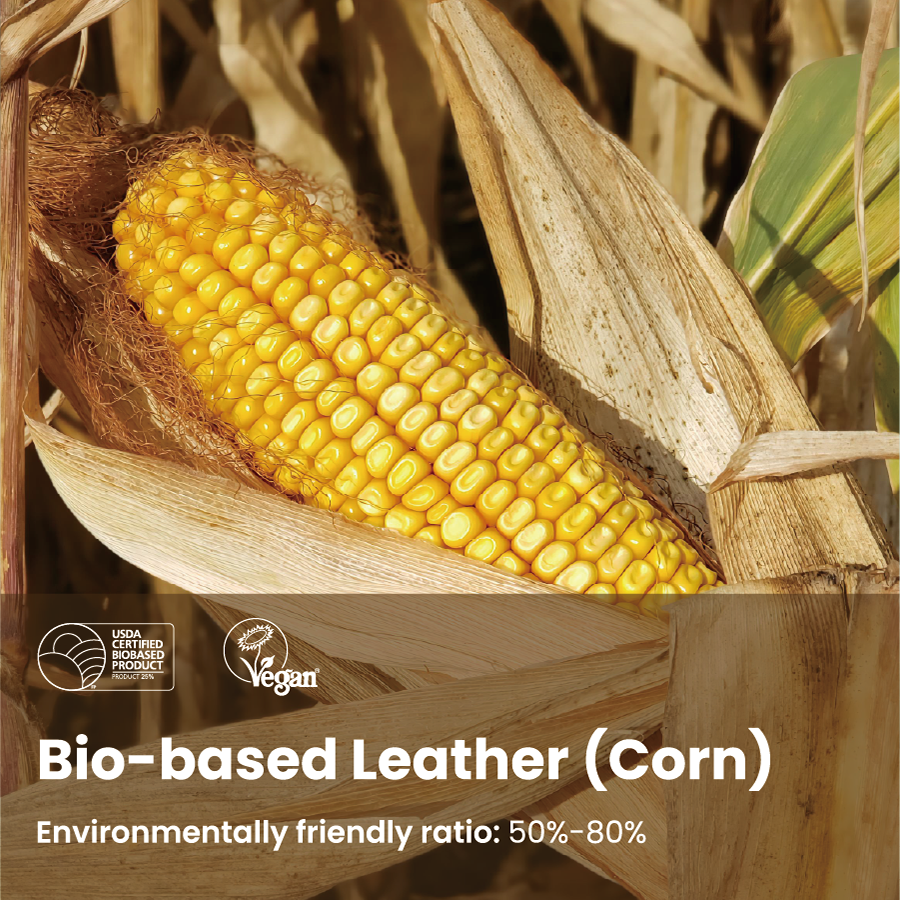

Biodegradable Innovations: Materials based on corn starch are fully biodegradable and align with emerging EU environmental regulations.

Advanced Protection: Aramid fiber, similar to that used in bulletproof vests, offers ultra-thin, fire-resistant qualities for ultimate protection.

Natural Elegance: Marbled PC finishes, achieved through advanced IMD processes, provide a naturally textured look that stands out in the market.

Operational Tips:

Always provide comprehensive material certification reports (e.g., SGS environmental tests) and consider small-batch trials (starting from 1,000 units) to gauge market acceptance before full-scale production.

Purchasing Decision Tree: A 3-Step Blueprint to the Perfect phone case

Step 1: Define Your Target Audience

Students: May prefer playful, cartoon-inspired phone case designs crafted from silicone or TPU.

Professionals: Often lean towards premium PC models or mixed materials that exude sophistication.

Eco-Conscious Consumers: Look for innovative, biodegradable materials that offer both style and sustainability—comparable to an apple leather phone case in aesthetic appeal.

Step 2: Assess After-Sales Implications

Review return rates and durability: silicone models generally exhibit a return rate of less than 3%, while PC models may see rates between 8%–12%.

Step 3: Calculate Overall ROI

Consider the premium potential of high-end materials, which can command up to a 500% price increase if marketed correctly.

This step is crucial for distinguishing between trends like black phone cases that offer a classic appeal and niche items such as a bluey phone case, which might capture a specific segment of the market.

Conclusion: From Material Selection to Customization—Your Comprehensive Guide

In the realm of phone case production, every decision from material choice to design can significantly influence market success.

By exploring materials like silicone, TPU, PC, mixed composites, and specialty options, manufacturers can tailor their products to diverse consumer needs and market segments.

Whether you’re considering a trendy apple leather phone case, classic black phone cases, or even experimenting with a unique bluey phone case, the key lies in understanding the material’s performance, customization potential, and cost implications.

Important: With a 24/7 sampling service, access to an extensive material library, and rapid mold development, our solutions are designed to accelerate your decision-making process.

For a wide selection of premium phone case options, please visit www.ctcase.com.

Contact us for a personalized consultation that ensures you choose the optimal material for your next phone case project.