Global opportunities in the bio-based materials market

Industry Analysis

The global wave of bio-based materials has arrived as a premium alternative to traditional materials.

According to the McKinsey Global Institute, up to 60 percent of the material inputs in today’s global economy could, in principle, be produced or replaced by biological means. Over the next 10 to 20 years, advances in the use of biology in materials, chemicals and energy production could generate $200 billion to $300 billion in growth for the global market.

Bio-based materials are good at reducing carbon emissions and recycling

Biobased materials are new materials and chemicals made from renewable biomass such as grains, legumes, straw, bamboo and wood flour. Compared with the production of traditional chemical materials, bio-based materials effectively reduce carbon emissions in the production process.

Under the transformation of raw materials, bio-based leather can replace most traditional leather materials (animal leather, artificial leather)

Compared with other synthetic leather, bio-based leather is more scratch-resistant and has a softer surface. At the same time, it can be a good substitute for animal leather, reduce the feeding of cattle and sheep, etc., which has a strong positive environmental impact.

Vegan leather is gaining more popularity than ever before

In the global fashion search platform Lyst recently released the “2021 annual fashion report” pointed out that in 2021 consumers to “vegan leather” search frequency increased by 178%. Retail researcher WGSN Instock’s data shows that from the first half of 2018 to the same period this year, the online availability of vegan leather products in the UK has more than doubled, and the US has increased by 54%.

Infinitum Global analysts predict that the global demand for vegan leather will continue to grow at an annual rate of 49.9%, and will reach $89.6 billion by 2025. And the Asian market will become the industry’s dominant.

This new type of leather products are gradually become fashionable.

Vegan Leather is a type of bio-based leather, which refers to leather products that are 100% free of animal ingredients and animal footprints in their manufacturing materials and processes, and do not undergo any animal testing.

Sustainable trend pushes vegan leather development

Sustainability becomes an important consideration in consumer decisions

Sustainable value is ranked fourth in consumers’ consideration when choosing a brand.

As consumers become more environmentally conscious, they will gradually become resistant to artificial leather. Leather based on plant fibers (such as apple peel, pineapple, cactus, etc.) and leather grown from cells such as mycelium leather has emerged. They can be used in various fields such as cars, shoes, sustainable phone case.

At the same time, BMW also became vegetarian.

BMW said that by using new steering wheel materials, the proportion of parts containing animal-derived materials in the vehicle has been reduced to less than 1%. This means these materials will not appear in visible areas such as paint, protective coatings and paints.

Uwe Kohler, Head of Development Automotive Interiors and Exteriors at the BMW Group, said: With a steering wheel made of high-quality, fully plant-based surface materials, we meet the expectations of customers who do not want to make any compromises in terms of look, feel and functionality. This innovation The material can withstand damage from wear, sweat and moisture and has all the desirable properties of leather. The new material creates a unique textured effect on the steering wheel.

BMW says its next-generation vehicles will offer leather-free options as an alternative. BMW is working with startups to develop bio-based materials. For example, Mirum™, which is 100% bio-based and petroleum-free, has the potential to mimic all the properties of traditional leather. Another new material, Deserttex™, is made from crushed cactus fibers and bio-based polyurethane.

How to monitor whether suppliers change materials?

1. There are currently not many leather suppliers on the market that can produce bio-based materials. Changing materials at will will damage the supplier’s goodwill.

2. Customers can take the product for bio-based testing to detect whether the product contains bio-based ingredients.

The bio-based content of certified products is divided into three quality levels. Products produced wholly or partly from bio-based raw materials can be certified under this scheme if they contain at least 50% organic carbon and contain at least 20% bio-based carbon. This is especially true in the field of mobile phone case supplier. Few companies spend their efforts on the research, development and production of environmentally friendly phone case.

About USDA certification

USDA certification is a certification system designed to provide consumers with reliable information and confidence, and is currently one of the most well-known certifications for organic food and other agricultural products. USDA Certification is a certification program administered by the United States Department of Agriculture (USDA) that identifies and verifies the sustainability and biobased origin of biobased materials used in agricultural and food products.

Relevant manufacturers must go through an auditing process to demonstrate that their products comply with USDA organic standards and obtain the organic certification logo for consumer identification. These standards not only meet the requirements in the United States but also apply to European agricultural USDA report processing.

In order to obtain USDA organic certification, producers need to submit an application and undergo an audit. Auditors inspect a producer’s farm, factory and all related materials to ensure they meet USDA’s organic standards. The audit will also include a review of inspection reports provided by the manufacturer at each stage to prove that their products meet USDA organic standards.

Once USDA organic certification is obtained, it can prove that the manufacturer has taken measures to ensure the quality and safety of the product, and help consumers make healthier and environmentally friendly choices.

Therefore, our leather suppliers have obtained these certifications, which means that the raw materials we purchase meet international requirements and are monitored by reputable certification agencies.

Our cactus leather supplier has now obtained USDA certification. For customers, this certification mark also proves the traceability, safety and reliability of our raw material products.

USDA Certified Biobased Product Label

USDA Certified Biobased Product Label consists of an icon, the percentage of biobased content, and additional text. This label provides consumers with information about the percentage of certified renewable bio-based ingredients in the product and/or its packaging. Consumers can trust this label because companies applying for the label must submit the required product information to the USDA and send samples to USDA-accredited laboratories for biobased content testing according to ASTM D6866 standard. The final test results meet USDA’s minimum biobased content requirements for the product category. *This label indicates a biobased content of 57% for the product and 32% for the packaging, and the product is eligible for the federal mandatory purchasing program.

Advantages:

1. Categorization: The label provides specific biobased content requirements for different types of biobased products.

2. Wide applicability: It covers almost all biobased industries, except for food, feed, and biofuels.

3. Permanent validity (as long as the product formula remains unchanged).

Information about certified products is publicly available on the USDA website.

4. To obtain USDA product certification, the product must meet the corresponding low biobased content requirement in the Biobased Preferred Procurement Program. For products not falling into any category, the low biobased content requirement must be above 25%.

Production processes of each type of material

Bio-based categories: Cactus leather, pineapple leaf (fiber), apple leather

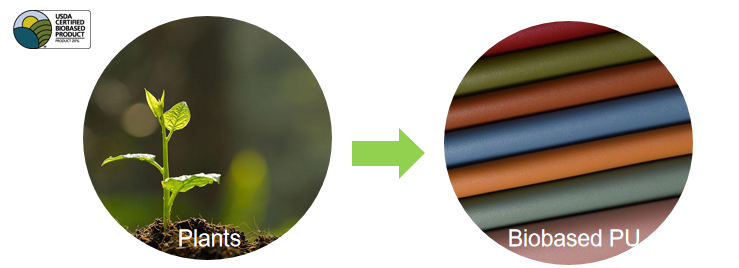

Biobased PU raw material:

Base on the organism itself or an extract from it. The plant resources: corn, bamboo, soybean, wheat, sugar beet and other starchy agricultural.

Cactus leather

It is a bio-based material that is more breathable than the ordinary vegan leather (synthetic leather) . Cactus leather comes from the prickly pear cactus, a fairly sustainable material.

Cactus Leather “Use with confidence, it won’t irritate your hands!”

The fiber is flexible and light: the texture is completely different from leather, soft to the touch, elastic and breathable, cactus leather can replace almost any animal skin.

Fashionable and environmentally friendly: Purchasing cactus leather products represents an environmentally friendly choice and is also a fashionable choice on the market. Choosing eco-friendly materials like cacti not only allows you to express your personality, but also allows you to show your support for environmental causes. At the same time, there is no need to sacrifice the quality and design of the product. It is not only environmentally friendly and sustainable, but also fashionable.

Save water resources and simple to make: first harvest mature cactus, clean and wash it, mash it, place it in the sun to dry for three days, separate the fiber from the dry covering, extract the powder, and mix it into bio-lipid. Moreover, the cacti does not require irrigation when growing, saving a lot of water resources.

Reduce carbon emissions and combat soil desertification: Cactus systems are good at retaining carbon in the soil. Sequestering carbon in soil results in fertile growing areas and reduced atmospheric carbon. Since carbon dioxide is the most common greenhouse gas, cacti’s ability to remove it from the atmosphere would help slow global climate change. Cactus can survive on arid land, effectively prevents soil desertification and helps reduce carbon emissions. At the same time, the cactus leather produced can also be completely biodegraded naturally. Cacti’s adaptability to the environment and ability to absorb carbon could be used to mitigate climate change

Cactus leather production process

1. Firstly, cut off a portion of the cactus without uprooting the entire plant. After some time, it will be able to regenerate.

2. Clean the cactus, then grind it into powder and sun-dry it. Use machines to process it into a powdered state. Mix it with non-toxic chemicals using machines to create an independent leather-like material.

3. Finally, use special machines to create textures on the material, and with the addition of dyeing, a high-quality leather product is produced.

Street brand Onitsuka Tiger

Transforming the upper of the classic Mexico sports shoe into a pure vegan cactus fiber material, combined with soft pastel tones, we present the new Cactful sneakers! Not only environmentally friendly but also fashionable, adding a touch of brightness to the summer!

Starting from the brand concept and background

Traceability of raw materials: Cacti grow on the land of Mexico, nature’s blessing for your feet.

Product background: For over half a century, the MEXICO 66™ shoe has been loved worldwide and is synonymous with the Onitsuka Tiger brand.

Collaboration concept: Introducing the MEXICO 66™ CACTFUL™, the production process aims to minimize environmental impact. For the first time, materials sourced from Mexican cacti are used, while retaining the iconic design elements of the MEXICO 66™ shoe.

Analysis of the raw material advantages, highlights, and concept of the product:

The MEXICO 66™ CACTFUL™ features a shoe upper made from over 20% cactus-based materials sourced from Mexico, developed in collaboration between DESSERTO® engineers and Onitsuka Tiger to meet the brand’s standards. Compared to traditional leather, the materials used in the MEXICO 66™ CACTFUL™ reduce CO2 emissions by approximately 84.8% during the manufacturing process. Additionally, the leftover cactus produced is being utilized for food purposes in the food industry. Apart from the main upper, other components such as the insole and shoelaces are also made from recycled materials.

MEXICO 66™ CACTFUL™ offers a range of colors specially designed for Onitsuka Tiger to enhance the soft textured characteristics of the cactus-derived material. The bold and elegant pastel tones are difficult to replicate in traditional leather, providing not only the suppleness and strength of cactus but also an imposing appearance. To maximize another strength of this material – its lightweight nature-special attention has been given to the midsole design to ensure a comfortable fit.

The design of MEXICO 66™ is rooted in the shoes Japanese athletes wore during the 1968 Mexico Olympics. The new product incorporates an innovative material derived from cactus, which grows on Mexican soil. Mexico, being one of the inspirational countries behind the birth of Onitsuka Tiger’s iconic model, is blessed with abundant natural resources.

While retaining the iconic design elements of the original MEXICO 66™, the new product is available in five colors to enhance the characteristics of this cactus-derived material, particularly its soft texture, which is challenging to achieve with traditional leather. Another feature of this cactus-derived material is its lightweight nature, making it suitable for footwear design, and the shoelaces and other parts also contain a proportion of recycled materials.

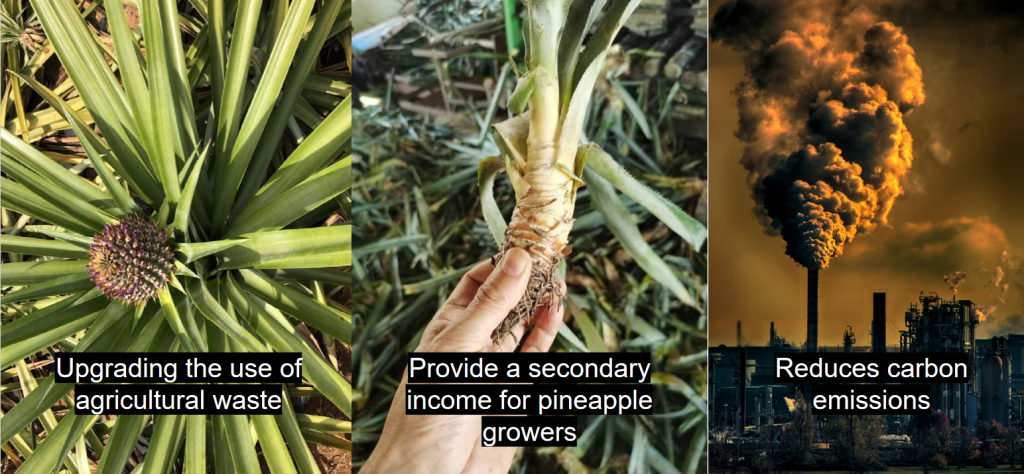

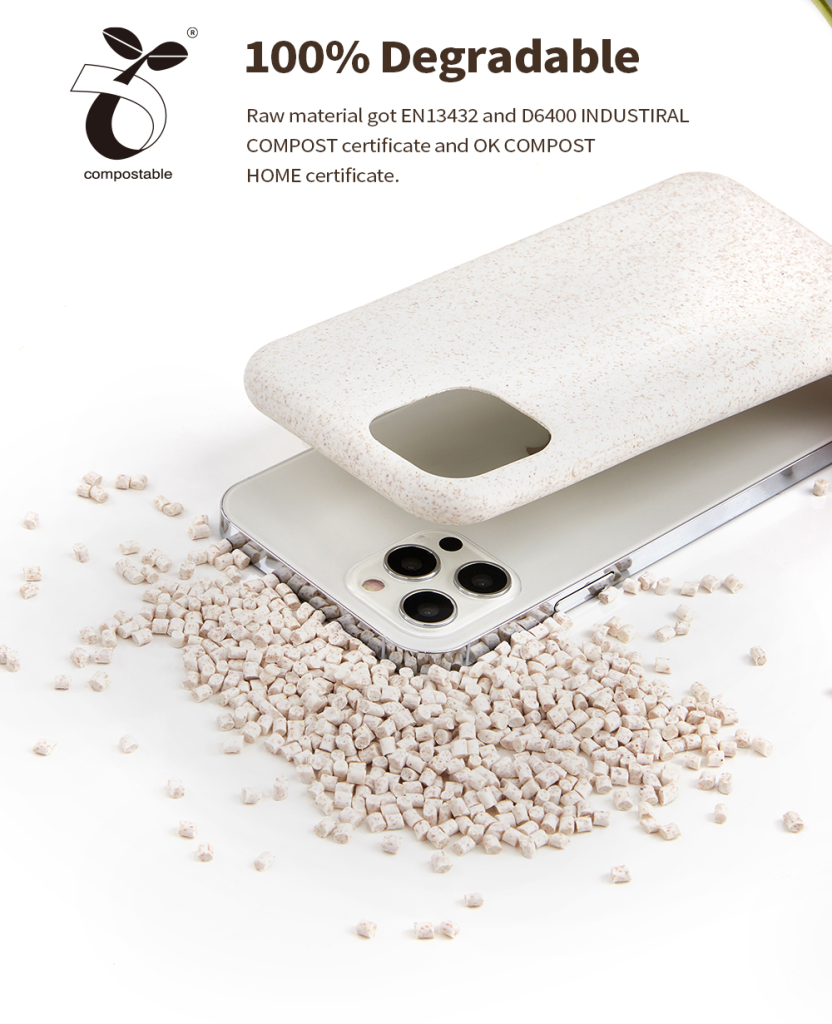

Vegan leather from Pineapple Fiber

This series of eco friendly phone case is made from plant fibers extracted from pineapple leaves. After the pineapple fruit harvest, pineapple leaves are usually discarded directly as agricultural waste. This is an effective upcycling of our agricultural waste, reducing environmental impact while generating additional income for farmers.

We provide pineapple hemp leather textile solutions to help our partner brands achieve their sustainability goals.

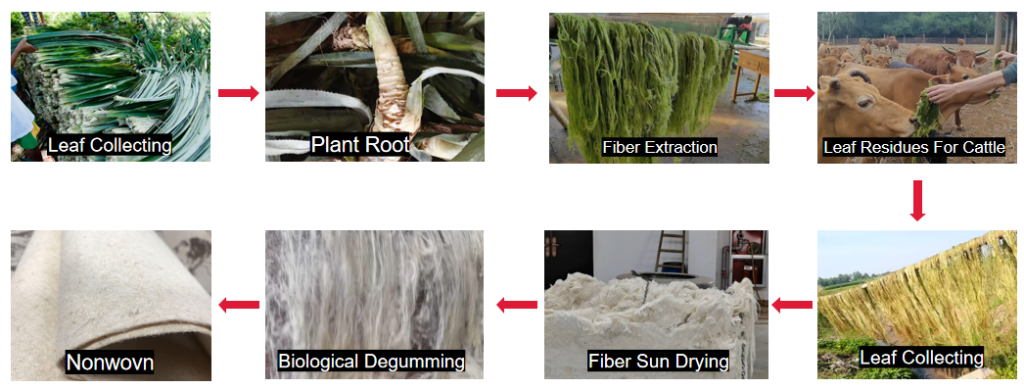

Production and manufacturing process

Special properties of pineapple leaf fiber

Pineapple leaf fiber material display

Apple scraps are a misplaced “leather”material

Vegan leather made from apples

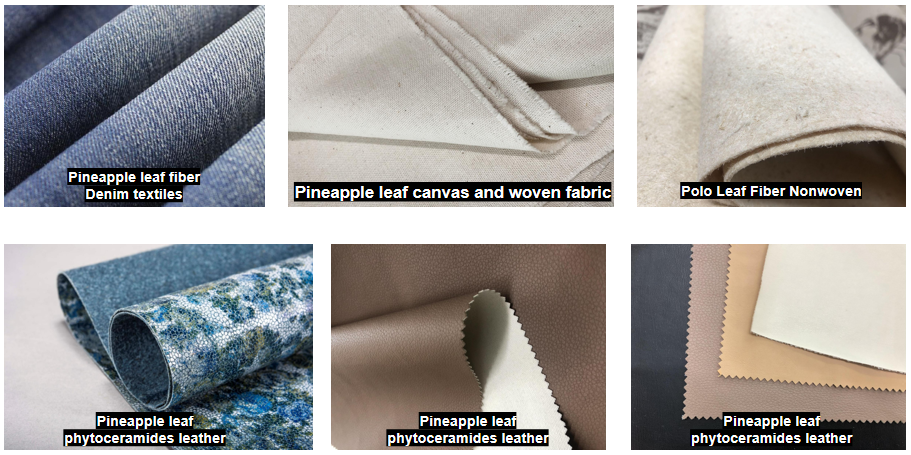

The apple leather alternative is a bio-based material made from pomace and peel left over from the juice and preserves industry.

Process: First, the recycled apple waste is made into powder, and then it is made into powder. This biomass powder is then mixed with other natural agricultural fibers through a process of combining with polyurethane and coating it onto the plant-based material.

Generally speaking, the bio-based content can vary, with no less than 50% mixed with 50% water-based PU. The result is a durable, eco-friendly, breathable material (thanks to its organic composition) that is smooth to the touch and suitable for making hard-wearing gadgets.

Source: Ariadne Consulting

The price of the product is low, the form is similar to animal leather or artificial leather, and the quality of the product is equal to that of the big brand counterparts.

– Water-based PU is non-toxic, non-hazardous and biodegradable

– Used for joint stability, plasticity, enhance product performance, make the material form and animal leather or artificial leather

– Balance between practicality and market pursuits, future enhancement of bio-based content

Apple Leather:

It may be possible to have good quality leather products and be environmentally sustainable

Durable, breathable and smooth touch feeling

Feels like genuine leather:The best thing about apple leather is that it can be used to make shoes, bags, belts, furniture, clothing, labels and accessories by producing quality handbags and countless other products with a snakeskin look and feel. It’s vegan, durable, waterproof and environmental protection characteristics are slowly allowing major international brands to replace the production of raw materials, and the process of environmental protection can create better products.

Environmental highlight:It recycles apple waste from the food and juice industries and upcycles it, such as the pulp, core, and skin that remain after juicing. Compared with animal fur, apple leather is more in line with the current consumer’s green consumption concept, both from the environmental protection and ethical level.

Our mission is to design ethical luxury goods for consumers who value aesthetics and craftsmanship and sustainability.

ADAR’s founders Luca Matteo Manuzzi, a fashion entrepreneur and creative in Zurich, and Willy Anne Wijnja, a designer in Florence, describe the Waver as a “vegan sneaker for the conscious generation,” with a vamp made of apple leather and recycled polyester. The 40mm thick outsole is made of recycled rubber, the lining is made of bamboo fiber, and the insole is made of apple leather and recycled latex.

The brand positions Waver as “quality footwear for discerning sneaker lovers who appreciate the importance of handcraft, modern design, innovation and environmentally friendly manufacturing.” The apple leather it uses to construct the upper and insole is “environmentally friendly, breathable, waterproof and durable,” according to ADAR.

Apple Leather is one of the frequent activists, with shoe and leather goods brands including Sylven New York, Samara and Good Guys Don’t Wear Leather all citing apple leather as one of their main fabrics

Cartier launched an innovative TANK MUST Solarbeat watch with a solar dial in April last year, and the strap material is selected from apple waste processing made of apple leather, to express the brand’s commitment in the field of protecting the environment and biodiversity. In addition, Italian high fashion brand Genny, French leather brand Poetique Paris also launched bags made of apple leather last year, and Chloe’s associate line brand See by Chloe and Tommy Hilfiger launched “apple leather” products earlier than 2020.

Phone bags, card bags, phone cases made from apple leather

Feels soft and delicate, easier to maintain

Almost indistinguishable from Classic Leather,it is slightly lighter and less prone to aging.

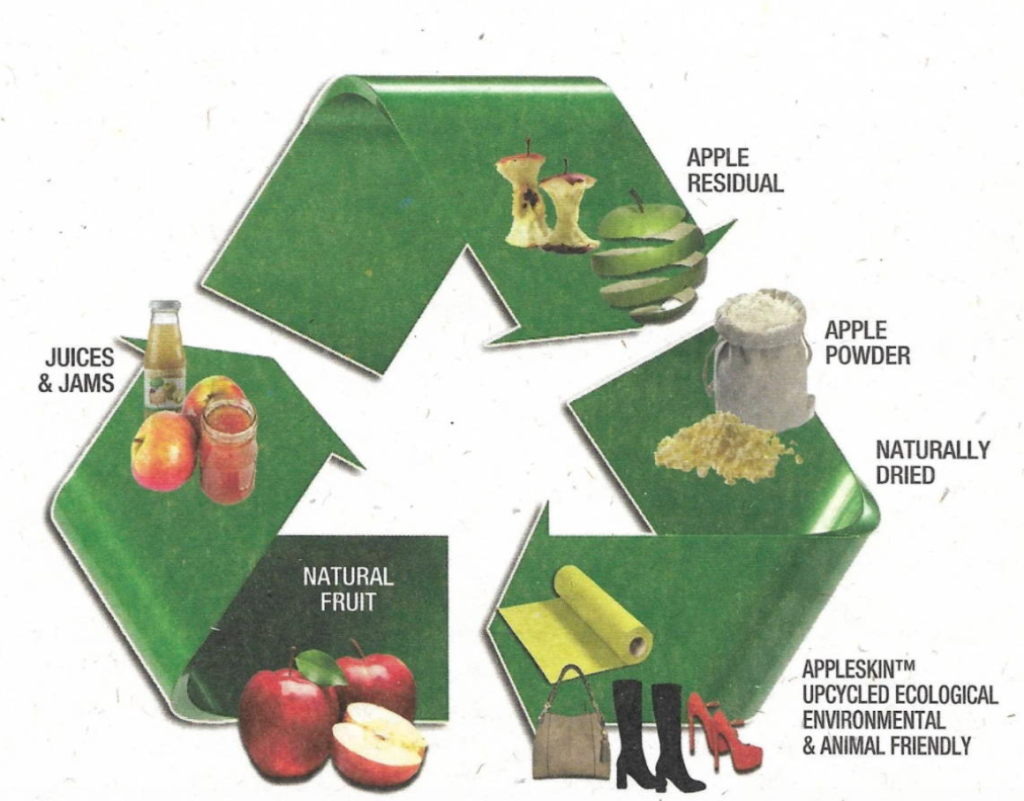

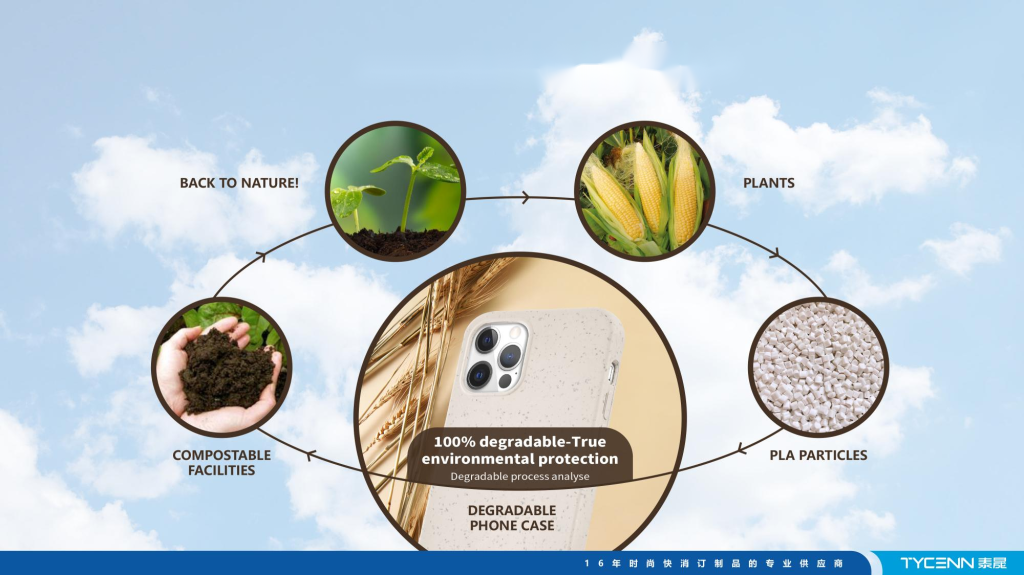

PLA FROM CORM

100% Biodegradable and compostable materials

C&T biodegradable products are made from a blend of PLA (polylactic acid), PBAT and plant fibers that can be completely decomposed into water and carbon dioxide under industrial composting conditions and tested to meet standard ISO 14855-1-2012, which guarantees their full compostability in industrial composting plants.

Customized biodegradable products can be marked with the biodegradable certification mark of the raw material on the outer packaging of the product, proving the environmentally friendly and harmless advantages of the raw material.

Bio-based hides (corn)

Starch, sugar and lipids are extracted from corn and converted through technology and processes to produce biosynthetic fibers, which can be applied to weave into bio-based materials. It has good biodegradability and can be converted into small non-toxic molecules such as water and carbon dioxide through biodegradation methods such as burning or composting, without worrying about causing environmental pollution.

100% biodegradable case is made of PBAT+PLA+Plant fiber,the material can be degraded by industrial composting.

The production process fully follows the principle of environmental protection

What is the principle of degradation?

The degradation process of environmental degradable plastics mainly involves biodegradation, photodegradation and chemical degradation. These three main degradation processes have synergistic and coherent effects on each other. Degradable plastics are completely degraded into water and carbon dioxide under industrial composting conditions.

Biobased PU

Sustainable sourcing and smart use of biomass can lead to the production of goods which are improved versions of traditional fossil-based alternatives or completely new items, and thus can contribute to savings in greenhouse gas emissions, to reducing waste and toxicity, and to a longterm shift away from finite fossil resources.

What C&T doing now?

Green material product development, assistant brand growth

The Innovation Centre continues to develop recyclable materials, biodegradable materials, apple leather, pineapple leather, recyclable PU leather and other low-carbon and environmentally friendly materials, combined with the latest technology and fashionable elements to create 100% original product designs to enhance the competitiveness of our clients’ brands in the market and help their economic benefits.

Actively engaging suppliers in low carbon initiatives

C&T actively collaborates with suppliers to create a green supply chain.

Encourage and guide suppliers to develop energy saving and emission reduction plans.

Actively promote strategic cooperation to jointly develop new environmentally friendly materials, processes and products.

Full carbon verification and carbon footprint certification

Companies carry out carbon footprint certification of their own R&D products and obtain relevant carbon footprint certificates

Active promotion of circular packaging

C&T has undertaken a comprehensive review of the use of disposable packaging at each production site to reduce the use of disposable cartons, wooden boxes, inner pallets and other packaging materials. The current production lines are all using recyclable packaging to transfer products and reduce the number of times non-environmentally friendly materials are used.

At the same time, the storage locations of materials in the warehouse have been re-planned to reduce the impact of non-environmental factors in the transportation of materials.