Introduction

A mobile phone case is not only for appearance, its most important function is to protect the mobile phone from harm. As a mobile phone case brand, how do you know whether the quality of the mobile phone case can protect the phone while still being beautiful, and whether the quality can still be guaranteed after long-term transportation?

A lot of this requires a series of experiments to test whether the phone case will fade and turn yellow under daily friction, long-distance transportation, and long-term use.

Why you need to know the quality of mobile phone cases

Brand image: The quality of mobile phone cases is directly related to the establishment and promotion of brand image. If the quality of the mobile phone case is excellent and can provide users with good protection, the brand will gain praise and word-of-mouth promotion from consumers. On the contrary, if the quality of the mobile phone case is poor, it will easily cause damage to the user’s mobile phone, which will have a negative impact on the brand and damage the brand image.

User satisfaction: A high-quality mobile phone case can provide users with a comfortable experience and reliable protection. When users purchase a good-quality mobile phone case, they will trust the brand more, feel satisfied with the brand’s products, and are more likely to buy the brand’s products again or recommend them to others.

Enhance market competitiveness: The mobile phone case market is highly competitive, and brands need to differentiate themselves from competitors by providing high-quality products. A mobile phone case that passes the drop test represents the brand’s confidence in product quality and its ability to stand out in the market. Excellent mobile phone case quality will enhance the market competitiveness of the brand.

After-sales service and warranty: Mobile phone case brands usually provide after-sales service and product warranty to solve problems that users may encounter during use. If the quality of the mobile phone case is good, the number of after-sales services and warranties that the brand needs to provide will be relatively small, which will help reduce the cost of brand operations and increase users’ trust and satisfaction with the brand.

Sustainable development: Mobile phone case brands pursue long-term sustainable development. Providing high-quality mobile phone cases can not only meet the needs of users, but also reduce the frequency of users replacing mobile phone cases, thereby reducing resource consumption and environmental burden. This will make the brand more in line with the sustainable development concept of contemporary society and win the recognition and support of consumers.

To sum up, the quality of mobile phone cases is crucial to brands. Excellent mobile phone case quality can establish brand image, improve user satisfaction, enhance market competitiveness, improve after-sales service and warranty, and promote sustainable development. Therefore, mobile phone case brands should always pay attention to and attach importance to the improvement and control of mobile phone case quality. What tests does a good mobile phone case go through?

Justified Image Grid error: there are no images to show, the “items” are empty.

Quality testing of mobile phone cases

Bending test

Test standard: Put the product into the bending testing machine, bend the product 90 degrees, and bend it back and forth 5 times

Test results: After the test, take out the product and check that there should be no delamination at the edges of the product.

Color fastness test 1

Test standard:

Dry wipe: Use a dust-free dry cloth on the surface of the test product, rub it back and forth 100 times with 200g gravity, and the length is 6cm.

Wet a white lint-free cloth with water (0℃-45℃), and rub it back and forth 100 times with a weight of 200g on the surface of the test product, with a length of 6cm.

Use a white lint-free cloth and an alcohol concentration of (95% ± 5%) on the surface of the test product, and rub it back and forth 100 times with a gravity of 200g and a length of 6cm.

Test results: No adverse phenomena such as discoloration or damage should occur after the test.

Color fastness test 2

Test standard:

Dry wipe with a dust-free dry cloth on the surface of the test product. The usage code is 200g gravity and rub back and forth 100 times. The length is 6cm to see if it meets the color card level three or above standard. Speed: rub back and forth 100 times in 200S. ②. Wet wipe with a white lint-free cloth dipped in water (0℃-45℃). On the surface of the test product, rub it back and forth 100 times with a gravity of 200g and a length of 6cm to see if it meets the color card level three or above.

Test results: After the test, the color card comparison was used to reach level 3 or above.

Adhesion test

Test standard:

Use a cutter to draw 10×10 (100) small grids of 1 mm×1 mm on the surface of the test sample. Each scratch should be as deep as the coating surface. Use a brush to clean the debris in the test area. The tape firmly sticks to the small grid being tested, and wipes the tape vigorously with an eraser to increase the contact area and strength between the tape and the tested area. Grasp one end of the tape with your hand and pull it quickly in the vertical direction (90 degrees). Remove the adhesive paper, conduct the same experiment 5 times at the same position, observe the damaged area of the coating, and make a judgment.

Test results: If the coating damage (falling off) area of the tested product is ≤5%, it is qualified; if >5%, it is unqualified.

Yellowing resistance test

Test standards: Put the sample into the anti-yellowing and anti-aging box, with the front side of the product facing up, keeping the front side smooth. The sample is placed 300-450mm away from the center of the rotating table, and illuminated with a 300w Osram lamp at 55°C for 24 hours.

Test results: Visual inspection of the product (when laying flat and looking directly at it, there should be no yellowing visible to the naked eye)

High temperature water boiling delamination test

Test standards: water temperature 80 degrees to 100 degrees, soaking time 10 minutes to 15 minutes, front screen printing side down, product completely immersed in water

Test results: There should be no peeling or delamination on the front of the product.

Destructive testing

Test standard: Use a knife to cut the middle part of the product, and tear off the two middle sheets with your hands.

Test results: After the test, there should be no delamination in the middle part of the product.

High and low temperature testing

Test standard: high temperature 60℃, test time 12 hours, low temperature -20℃, test time 12 hours, one cycle, total test time 24 hours

Test results: After the test, the product must not be open/cracked or deformed.

Precipitation test (constant temperature and humidity)

Test standard: Place the product in a thermostat with a temperature of 60°C and a humidity of 89%. The test time is 288H.

Test results: After the test, the product must not produce powder or oil.

RCA tape test

Test standard:

Use a NORMANRCA abrasion tester to install a special paper tape, apply a load of 175g and test for 30 cycles.

Test results: There should be no wear on the surface after the test

Artificial sweat test 1

Test standard:

Soak lint-free cloth in alkaline artificial sweat with pH 4.7±0.2, then wrap the product skin, seal and place the product at 50 ± 2°C, 95% ± 3% RH, and test for 24 hours

Test results: There should be no corrosion, peeling or other adverse phenomena on the surface after the test.

Artificial sweat test 2

Test standards: Artificial sweat test: high temperature 60℃, humidity 60%, test time 48 hours, place at room temperature for 4 hours, do a hundred grid test and check whether there is peeling or delamination on the surface of the product.

Test results: Whether there is peeling or delamination on the surface of the product.

Eraser test

Test standard: Use a special eraser to grind horizontally on 400-grit sandpaper, apply a load of 200g, and rub back and forth on the product surface for 100 cycles at a speed of 40 to 60 times/with a stroke of about 20mm.

Test results: After the test, there should be no scratches or other adverse phenomena on the surface of the product.

Pencil surface hardness test

Test standard: Use pencil hardness instrument, Mitsubishi pencil: H/H1/H2/H3H/H4/H5/H6/H7/H8/H9, on the surface of the product under the conditions of negative gravity: 500g, angle: 45 degrees Draw a line, the length of the line: 3-4cm. After the line is drawn, wipe it clean with an eraser/alcohol. If it is judged, 1 out of 3 is used as the standard.

Test results: After the test, there should be no scratches or other adverse phenomena on the surface of the product.

Installation test

Test standard: Put the phone into the phone case and then remove it, no other tools (only manual), number of cycles: 1000 times

Test results: After the test, the phone must not be damaged and the buttons must not be damaged.

Salt spray test

Test standard: PH value is 6.5~7.5, test room temperature is 35°C, saturated pressure barrel temperature is 47°C, compressed air pressure is 1.5, and test time is 48H.

Test results: After 24 hours of testing on the product’s hardware camera ring/hardware buttons, no rust, rust spots, or oxidation was found.

Sunscreen Hand Cream Test

Test standard: Apply the product surface with a cotton swab, test at a high temperature of 60°C and a humidity of 60% for 48 hours. After leaving it at room temperature for 4 hours, do a hundred grid test and check whether there is peeling or delamination on the surface of the product.

Test results: After the test, no peeling or delamination on the surface of the product was found.

Weather resistance test

Test standard: Temperature: 20℃±5℃ Relative humidity: below 70%, 1 per color, tested in an environment with water spray (humidity 90%RH), ultraviolet irradiation band 100~800nm must reach more than 24H, check after testing Whether the product is discolored or corroded.

Test results: After the test, no discoloration or corrosion was found on the product, and the results were OK.

Nail test

Test standard: Use a PMMA board to press on the surface of the product, back and forth 100 times. There is no coating damage or peeling off on the surface. The test result is OK.

Test results: No coating damage or peeling occurred in the test

Drop test

Test standard: Test the 4 sides and 6 corners of the product (once for each part) at a height of 100CM. After the test, the inner packaging and color box packaging are not crushed or damaged, and the product does not fly out of the packaging or fall off.

Test results: After the test, it was found that the packaging box was deformed, and no packaging products were found to fly out or fall off.

Alcohol abrasion resistance test

Test standards: wrapped in a dedicated test head, the model of the dust-free cloth is CanmaxTA9008, the area of the test head is about 1CM, the weight is 200g, and the test head is rubbed back and forth for 100 cycles

Test results: There should be no corrosion, peeling or other adverse phenomena on the surface after the test.

Color transfer test

Test standard: color transfer test: color transfer test: weight 500G, (consumables PU, ABS, PS, PVC) high temperature 60℃, humidity 60%, test time 48 hours

Test results: After the test, the color card comparison was used to reach level 3 or above.

White vinegar test

Test standard: Use 5% white vinegar → pour into the box, immerse the product for 4 hours and then rub it back and forth 100 times with a steel wool weight-bearing 1000G wear-resistant test instrument, with a length of 6cm

Test results: 3 PCS showed no peeling after the test

As the world’s leading manufacturer of mobile protective cases, C&T has a mature inspection and quality system.

Raw material supplier screening: C&T establishes cooperative relationships with reliable raw material suppliers and conducts strict screening of suppliers. Only suppliers that meet international standards and C&T’s internal requirements can provide raw materials.

Strict production process control: C&T strictly controls the production process of mobile phone cases to ensure that every link meets quality standards. From design to processing and manufacturing, each link is inspected and verified by a dedicated quality control team.

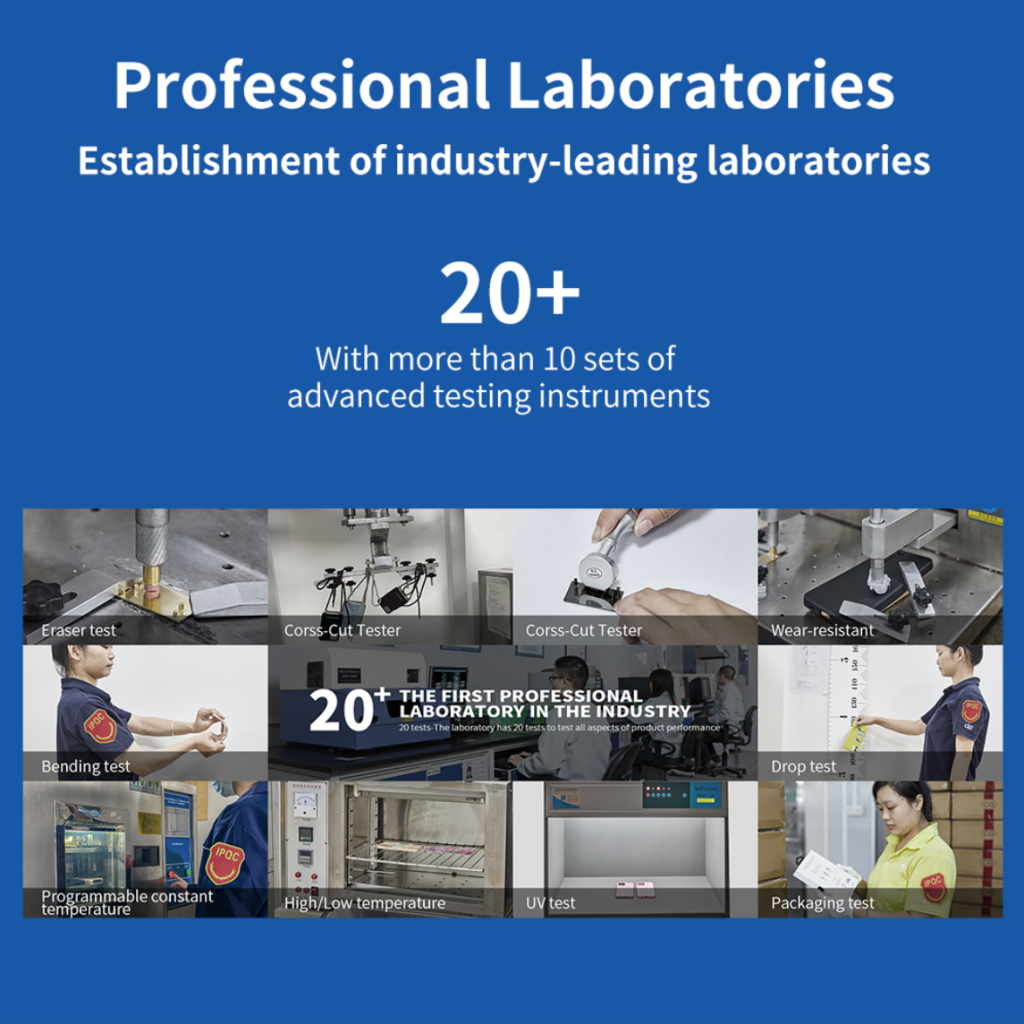

Quality testing equipment and methods: C&T has invested in advanced quality testing equipment and adopted a variety of effective quality testing methods. This includes physical performance testing, durability testing, chemical composition analysis, etc. to ensure that the quality of the phone case meets the requirements.

Third-party certification and testing reports: C&T has established cooperative relationships with a number of authoritative third-party testing agencies to conduct independent testing and certification of mobile phone cases. Relevant test reports will be issued by third-party organizations to provide an objective and authoritative assessment of product quality.

C&T strictly controls the quality of mobile phone cases to ensure that it provides high-quality mobile phone cases to brand owners. This not only helps the brand establish a good image and improve customer satisfaction, but also enhances the brand’s competitiveness in the market. At the same time, C&T is committed to promoting sustainable development and achieving sustainable development goals by reducing resource consumption and environmental burden. C&T will continue to improve its quality management system to meet changing market demands and customer expectations, and provide mobile phone case brands with continued high-quality products and services.