With growing awareness of the environmental impact, many consumers are looking for more eco-friendly alternatives to everyday products such as phone cases. The eco-friendly wheat straw sustainable biodegradable phone case is one such choice. The focus of this article is eco-friendly phone cases.

Wheat straw is the material.

A renewable resource, wheat straw is made from the remaining stalks of wheat plants after the grain has been harvested. It is an agricultural by-product that would otherwise be regarded as waste. The production of phone cases from wheat straw contributes to waste reduction and sustainability. Below are some benefits of wheat straw phone cases.

- Sustainability

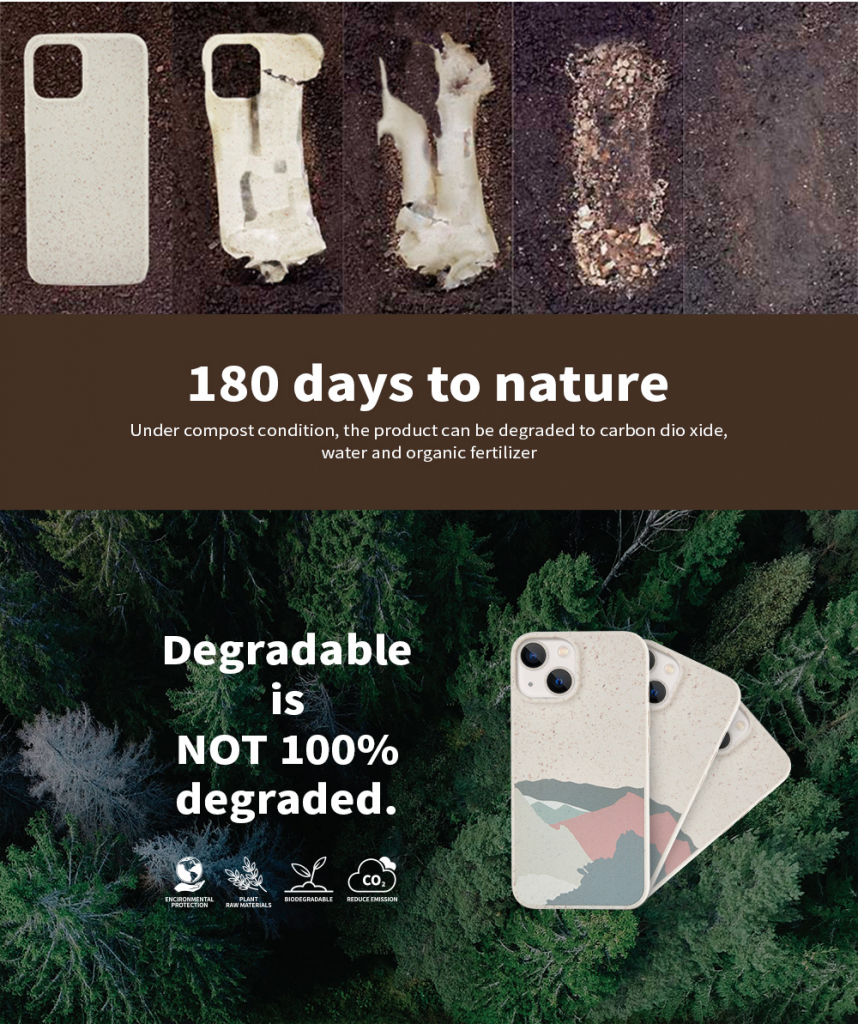

The sustainability of using wheat straws for phone cases is one of its major benefits. In contrast to customary plastic phone cases, a wheat straw case will decompose over time, lessening its environmental impact. It is more eco-friendly than conventional plastic casings because of its biodegradability.

- Durability

Wheat straw phone cases are still sufficiently strong to protect your phone whilst being a more environmentally friendly choice. They are made of a resilient material that is ideal for daily usage and can resist normal wear and tear.

- Design

Wheat straw phone cases are available in a number of designs and colors, so you may find one that matches your own style. The wheat straw’s peculiar texture and distinctive appearance distinguish it from conventional plastic phone cases.

The Process of Creating Eco-Friendly Wheat Straw Phone Cases.

Wheat straw phone cases are created using a technique known as “compression molding.” The first step in creating a wheat straw phone case is to collect the remaining wheat straw stalks. To get rid of any pollutants, these stalks are washed and treated. The cleaned stalks of wheat straw are then ground into a fine powder. To hold the substance together, this powder is then combined with a binding substance, such as cornflour or natural resin. Then, a mold in the form of a phone cover is filled with the wheat straw powder mixture and the binding agent. After that, the material is compressed and the mold is heated and pressurized to create the phone case.

After the phone cover has been created, it is taken out of the mold and put through a polishing process to eliminate any sharp edges or surface flaws. This could entail painting, cutting, or sanding. The phone case must be packaged before it can be sold as the last step in the formation process.

Why choose us?

C&T is ODM/OEM, professional manufacturer. We have more than 15 years of experience. We are a one-stop customization service for digital accessories. If you are also concerned about the customized products we believe we can bring value to you feel free to contact us.